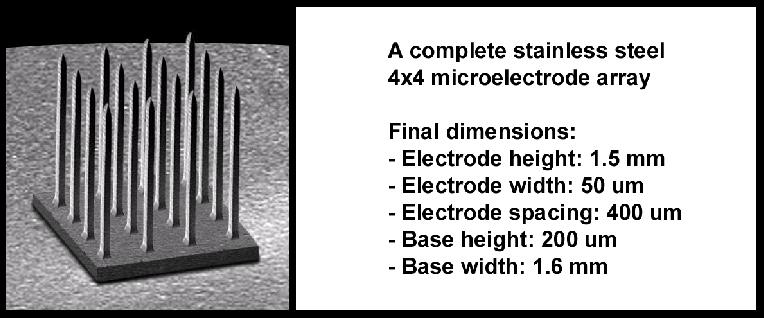

The approach chosen by Polystim requires a reliable brain/device interface adapted to an environment that is as harsh as it is delicate. In order to stimulate the cortex and produce well-defined bright spots with low currents, the best procedure is to use microelectrode arrays that penetrate the brain to a depth of ~ 1.5 mm. These electrodes must show low electrical impedance, excellent biocompatibility and good mechanical strength despite their high aspect ratio.

Our arrays are machined from bulk stainless steel or titanium by an EDM process. The surface of the metal is then electrochemically treated prior to the deposition of the platinum stimulation sites at the tip of the electrodes. An insulating epoxy base and a biocompatible coating complete the fabrication of the steps.

Several microelectrode arrays are now being built for in-vivo testing. The first implantation results and the great flexibility of our device will allow fast optimization of its properties.